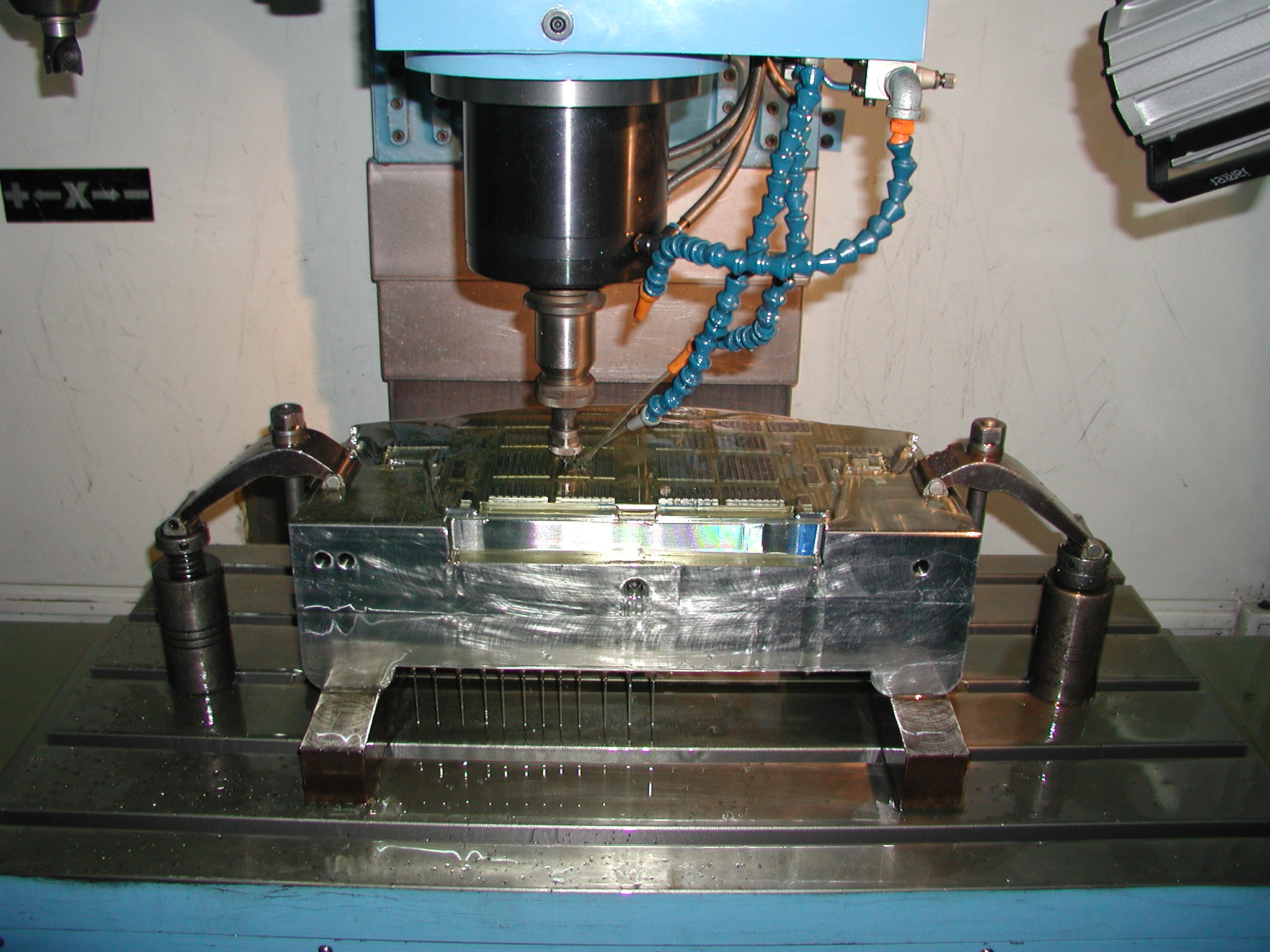

Core Mold Making and molding Technology

Intertech specializes in running various of precision plastic injection mold making and molding products projects , Collapsible core mold,Interchangeable core mold,Core pulling mould, for examples, the project components of smart phone, electronic items, smart housing device, digital 3C devices, camera, optical lens, plastic medical parts..etc. We have full ranges of injection molding machine, 50-250T in house, 200-3000T in associated party

Core Mold Making and molding Technology - Application Examples:

products projects , for examples, the project components of smart phone, electronic items,

smart housing device, digital 3C devices, camera, optical lens, plastic medical parts..etc.

We have full ranges of injection molding machine, 50-250T in house, 200-3000T in

associated party.

We have small size of screw shot volume with high speed injection

machine for running the kind of thin wall item mold and molding project for customer.

Intertech’s engineering experience and knowledge includes the application of the materials

of plastics, silicone rubber, liquid silicone rubber and metal etc.

I f customer have different material to be applied, processing and assembly,

we can help customer to make the proper injection mold and molding, compression mold

and molding, metal die and punching parts.

Secondary processing, for examples, printing, spraying, assembly, packing & shipping to

customer’s appointed destination can be managed very well in Intertech per customer

requirements. In our team association, we have the technology and equipment needed for

secondary processing. Welcome to send your project to us !

沒有留言:

張貼留言