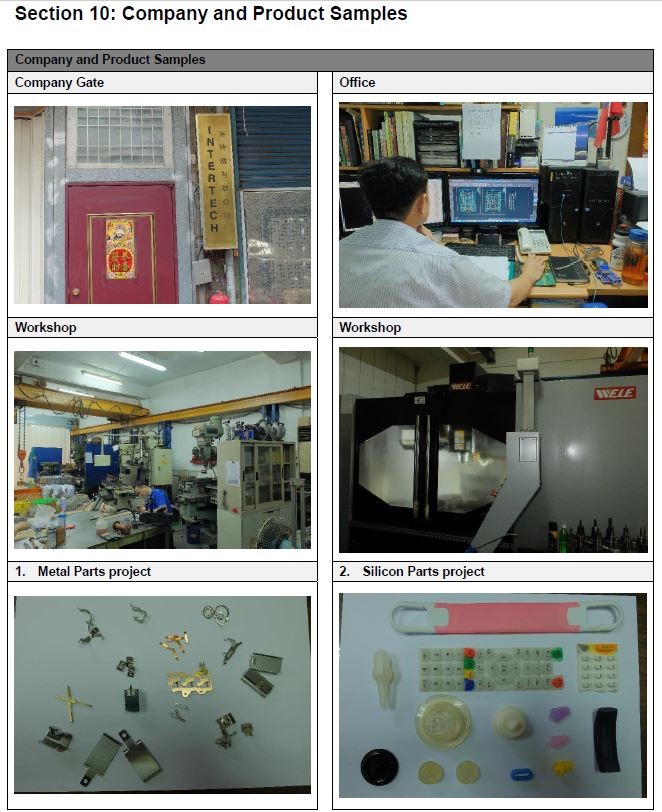

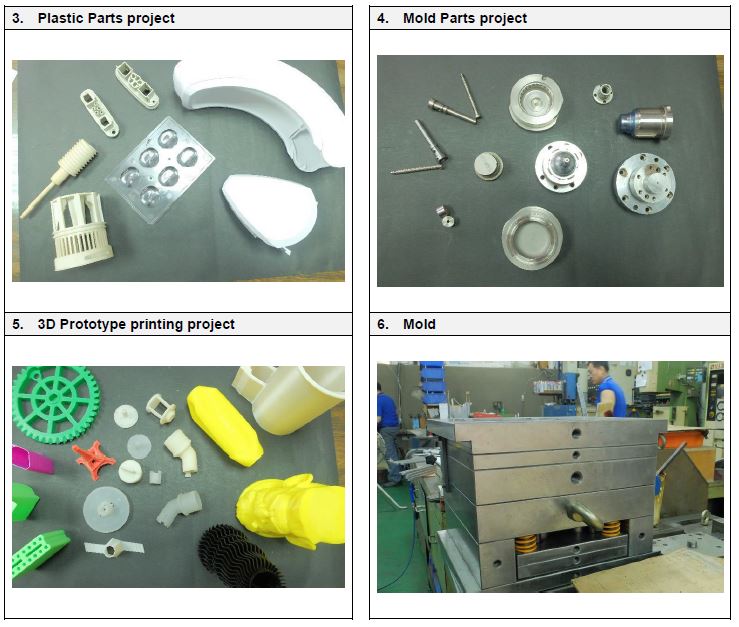

Intertech is a professional product design, product development, product design and development, parts manufacturer,product and packaging design services Supplier. Find more product design, product development & parts manufacturer serrvices information here or contact us for full service.

Intertech helps customer to do or improve their product design and development in order to make eventually the best possible tooling design, manufacturing and product mass production efficiency in target.

Intertech is a professional product design, product development, parts manufacturer services Supplier. Find more product design, product development & parts manufacturer serrvices information here or contact us for full service.

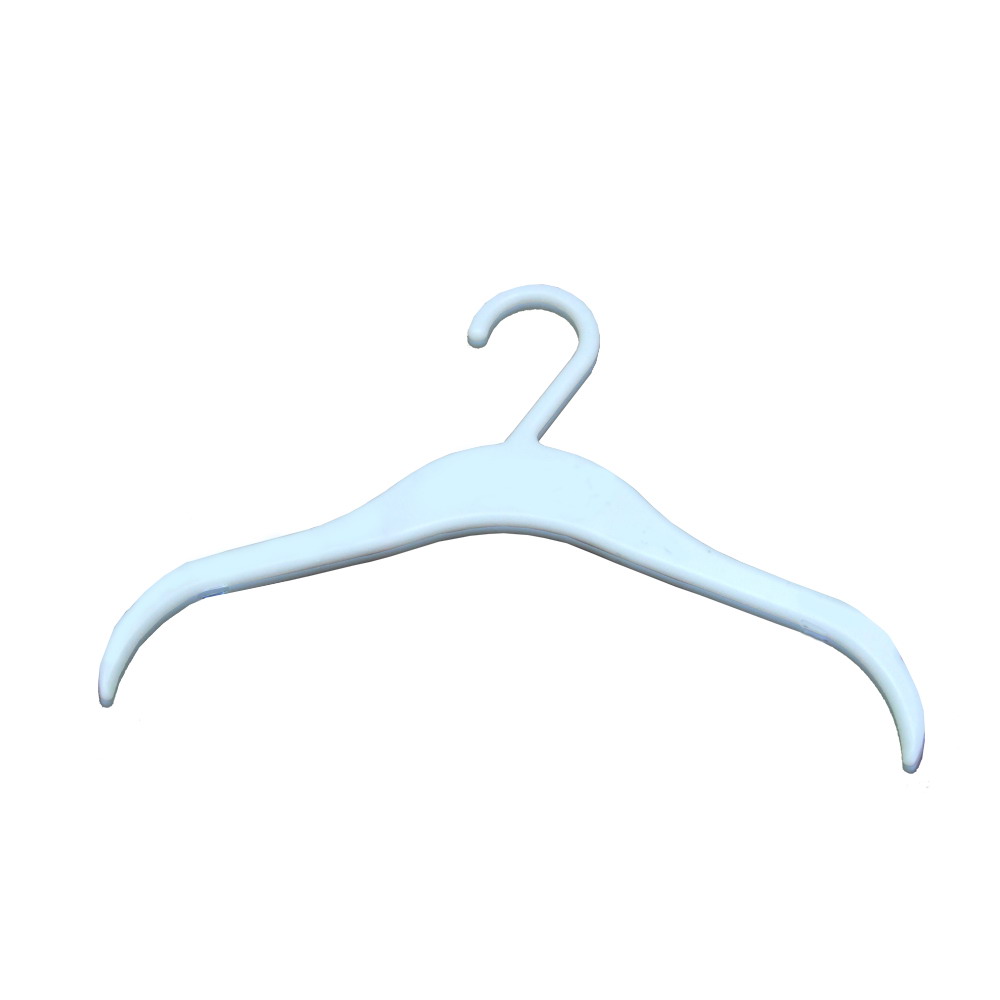

Plastic product Design and development

Intertech provide good plastic oriduct design,design for plastics,industrial product design service.

Intertech helps customer to do or improve their product design and development in order to make eventually the best possible tooling design, manufacturing and product mass production efficiency in target.

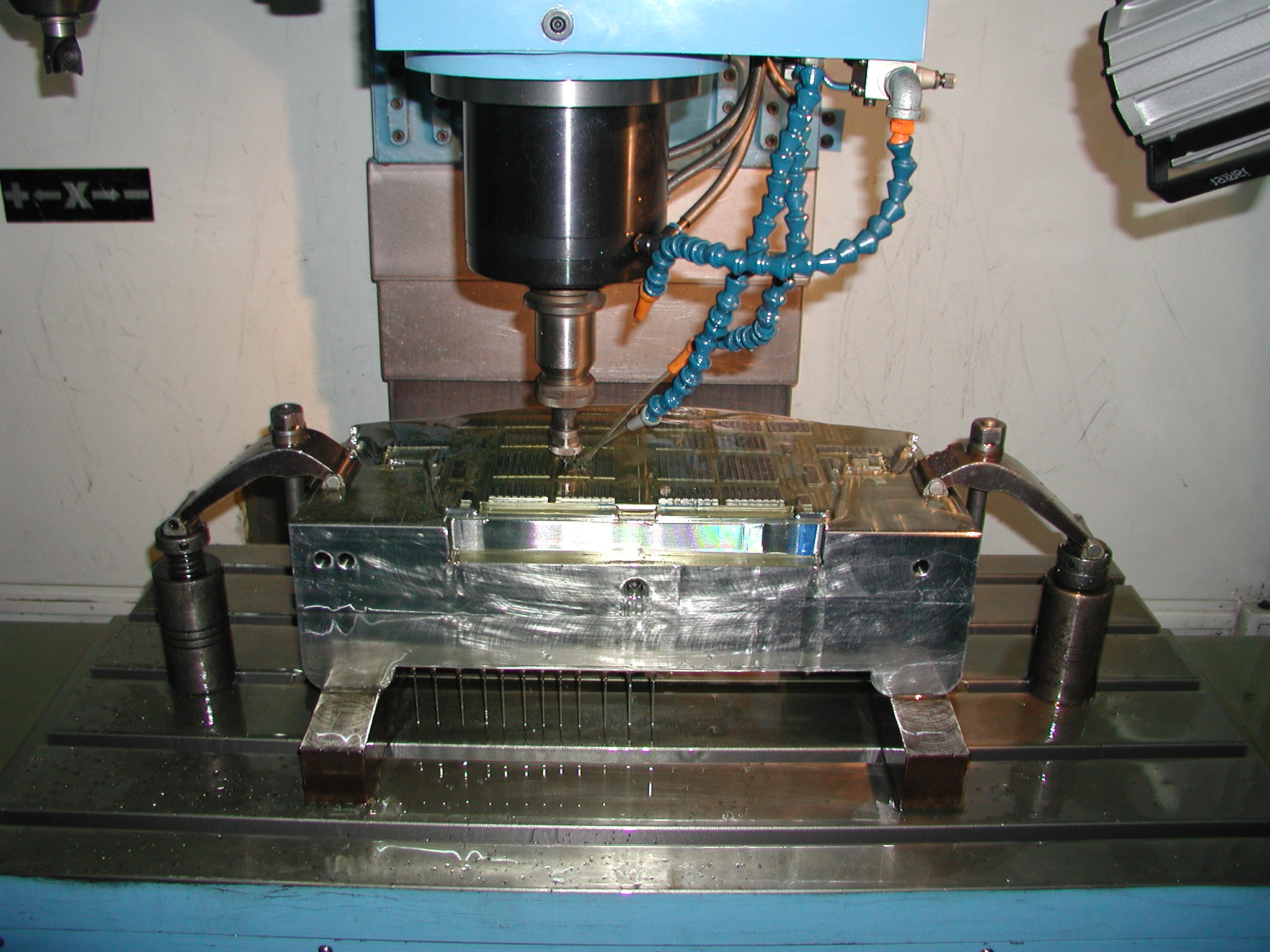

With more than 30 years experience, Intertech provides complete Product development, including product design consultancy and prototyping services.

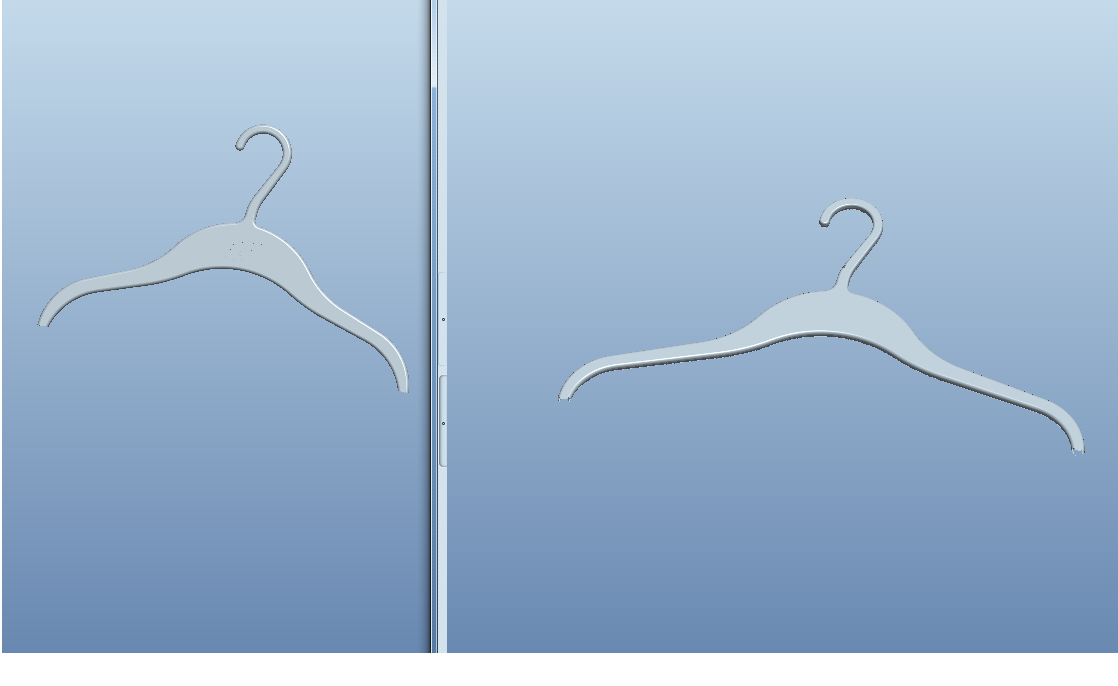

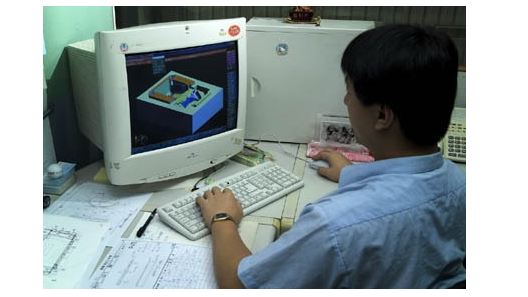

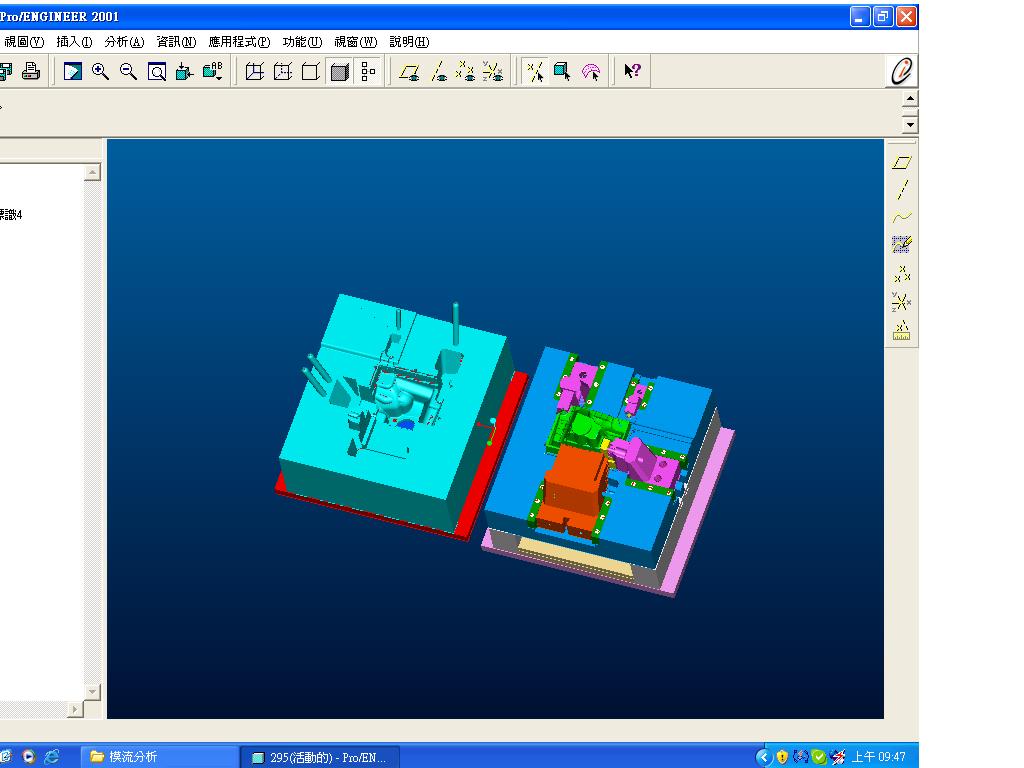

Design software our engineer use

Our engineers utilize the latest software including Pro/ENGINEER, SolidWorks used

for both product and tool design.

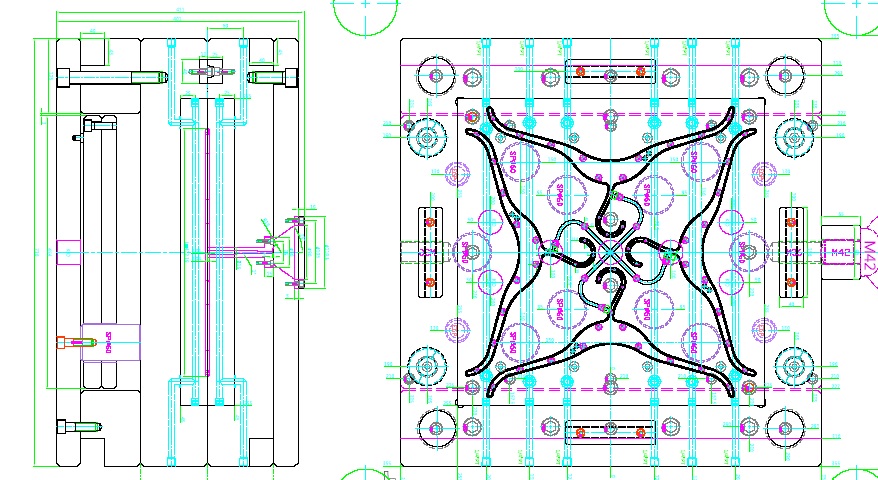

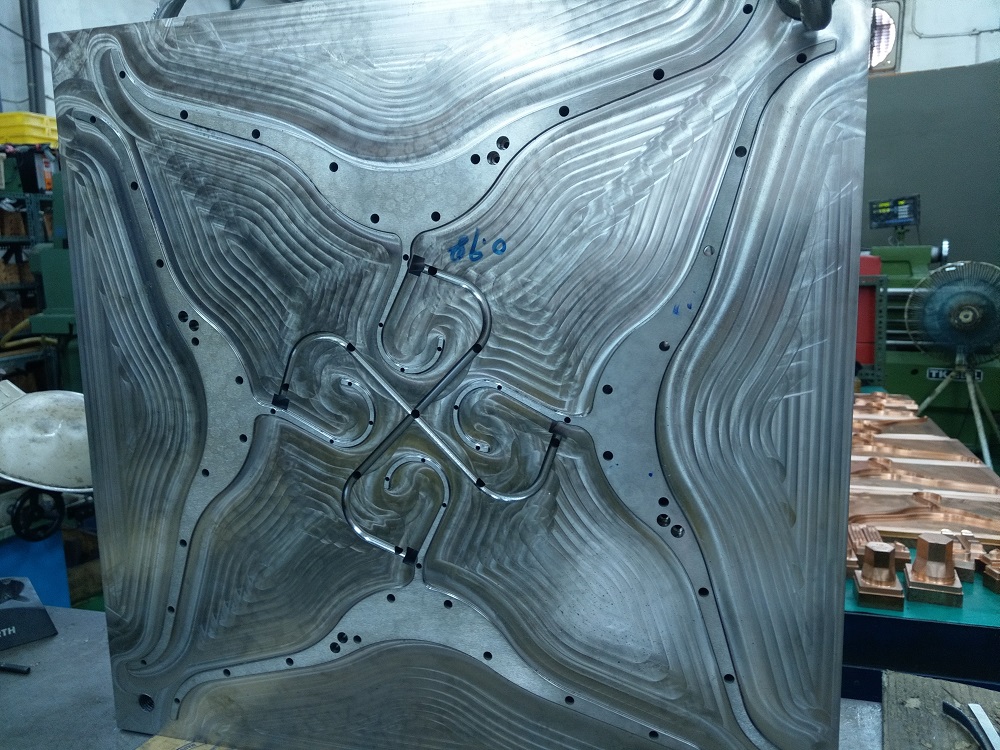

Intertech also provide mold flow simulation analysis service to help checking product design and mold design

Intertech also provide mold flow simulation analysis service which can provide a predictive view for checking product design and mold design.

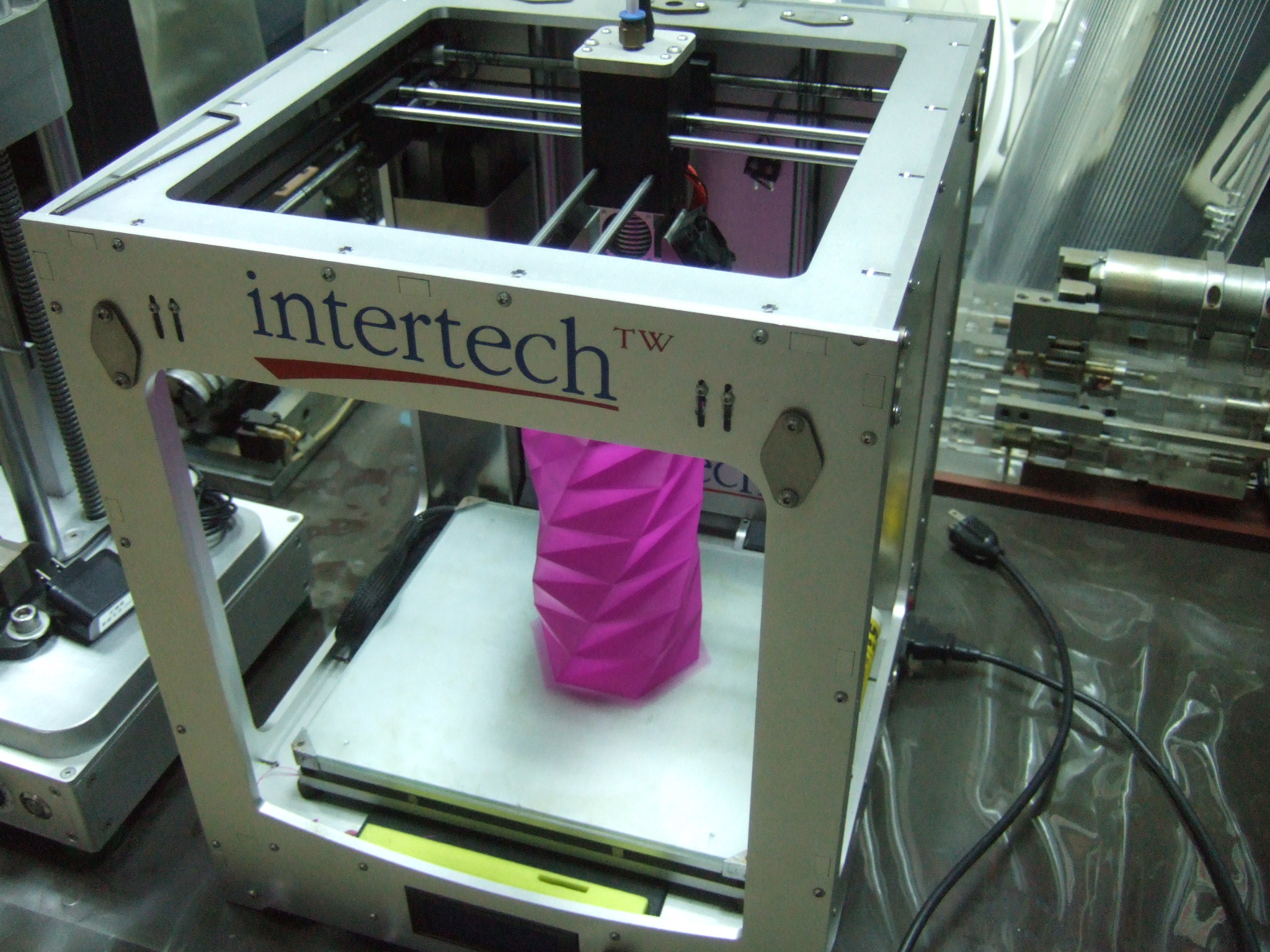

Intertech has in-house advanced 3D printer to help customer to prototyping their product design and idea.

Intertech has in-house advanced 3D printer to help customer to prototyping their product design and idea.

https://www.taiwanmoldmaker.com/product/plastic-product-design-and-development