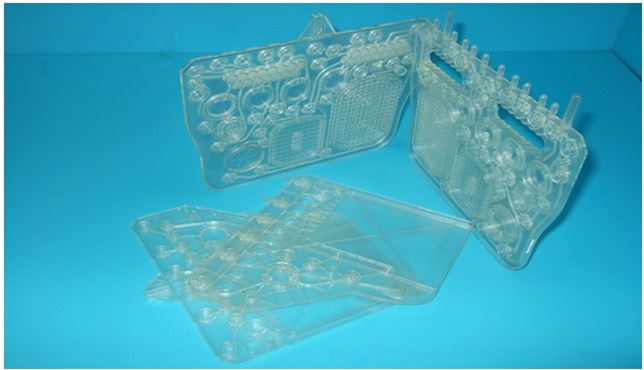

Intertech is a leading manufacturer for Medical & pharmaceutical equipment mold, plastic injection molding companies, medical devices mold and medical components mold and pharmaceutical product development,Medical plastic molds,Medical Silicone Molding Capabiliy medical plastic molding,medical moulding, medical molding, medical manufacturing, medical assembly, medical contract manufacturing, mold in Taiwan. Intertech's services include prototyping, tooling, lab testing, sampling, pilot run, mass production and assembly.

Our customer's concept of products will be brought out from design medical & pharmaceutical equipment molding to the discussion to its completion through our designers and engineers.

In recent years, Intertech gradually raises up our medical & pharmaceutical equipment molding design level to fulfill every customized molding equipment project. For examples, for fulfilling each customized medical & pharmaceutical equipment molding making project, when making those critical molds project, many kinds of slots, many kinds of material are needed in molding in one same mold or assemblied in one same mold. By doing this, we have to design the machining programming procedure with bigger capacity, plus, with high deep hole cavity machining capability and high stability procedure to accomplish this job. Eventually, such way will increase the medical & pharmaceutical equipment molding machining difficulty. However, Intertech can cooperate with customer’s requirement to adjust mold machining processing for satisfy each customer’s requirement.

Project development

and packaging applications. Per customer’s demand, we will discuss the raw material required,

the color master batch requires, mold making size required, molding machine size required,

cycle time estimation, production time calculation report…etc with customers. After that,

parts design service, mold engineering service, mass production arrangement, post assembly

service or post machining service are also provided.

Each mold and molding projects case, we will see client specifications to serve the needs of a

wide variety of industries. Our injection mold technology have D&B D-U-N-S compliant

working system and meets high industry standards. We can mold any plastic, metal and

rubber projects for customers. We have advanced machinery equipment to provide small

to larger mold projects and also manufacture thermoplastic, engineering plastics, silicone

rubber and metal parts.

Welcome industrial designer, product designer,crowd founding group,

factory manager to cooperate with us!

(GET

STARTED NOW to get Quick Qutation!)

https://www.taiwanmoldmaker.com

沒有留言:

張貼留言