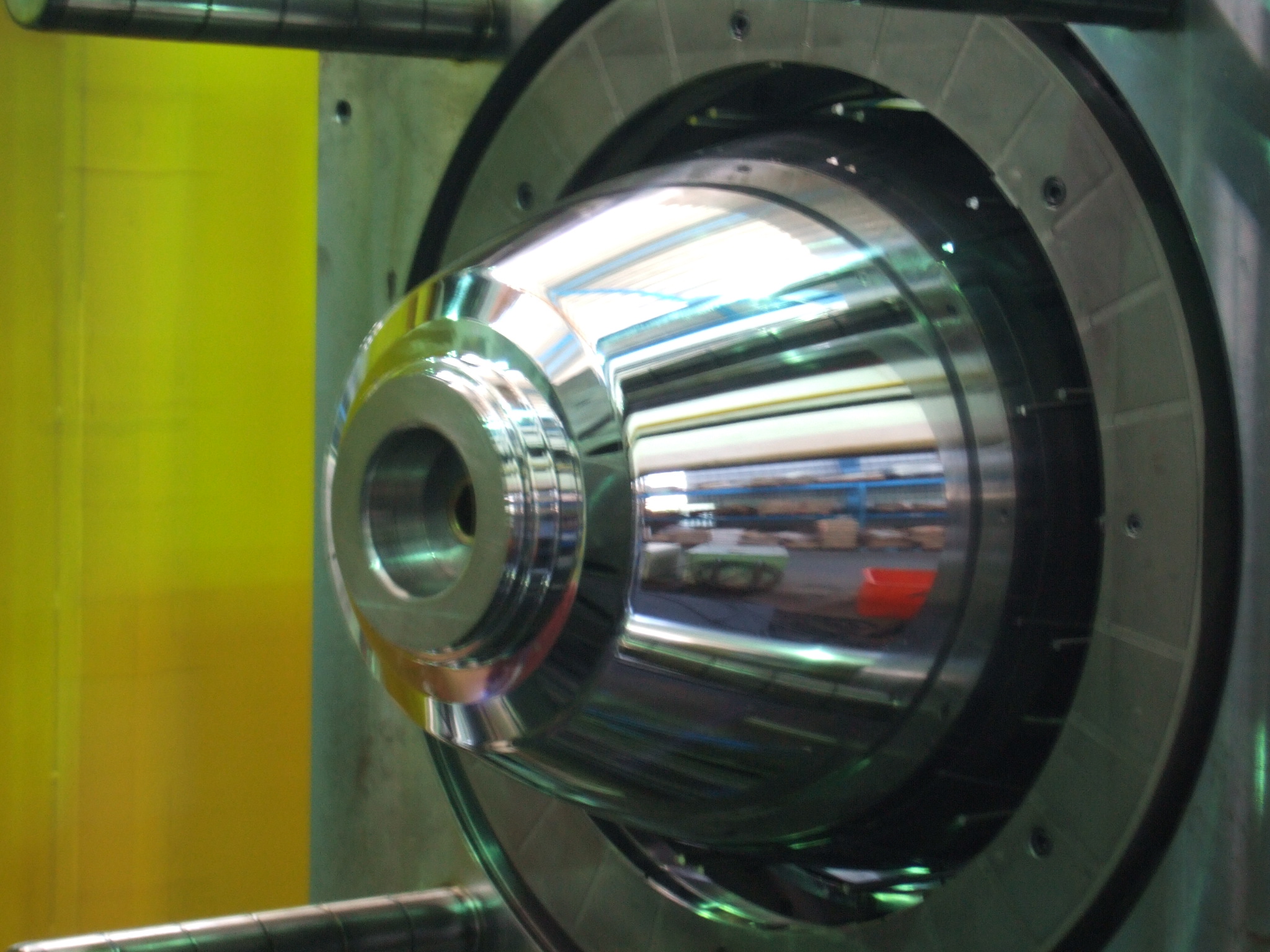

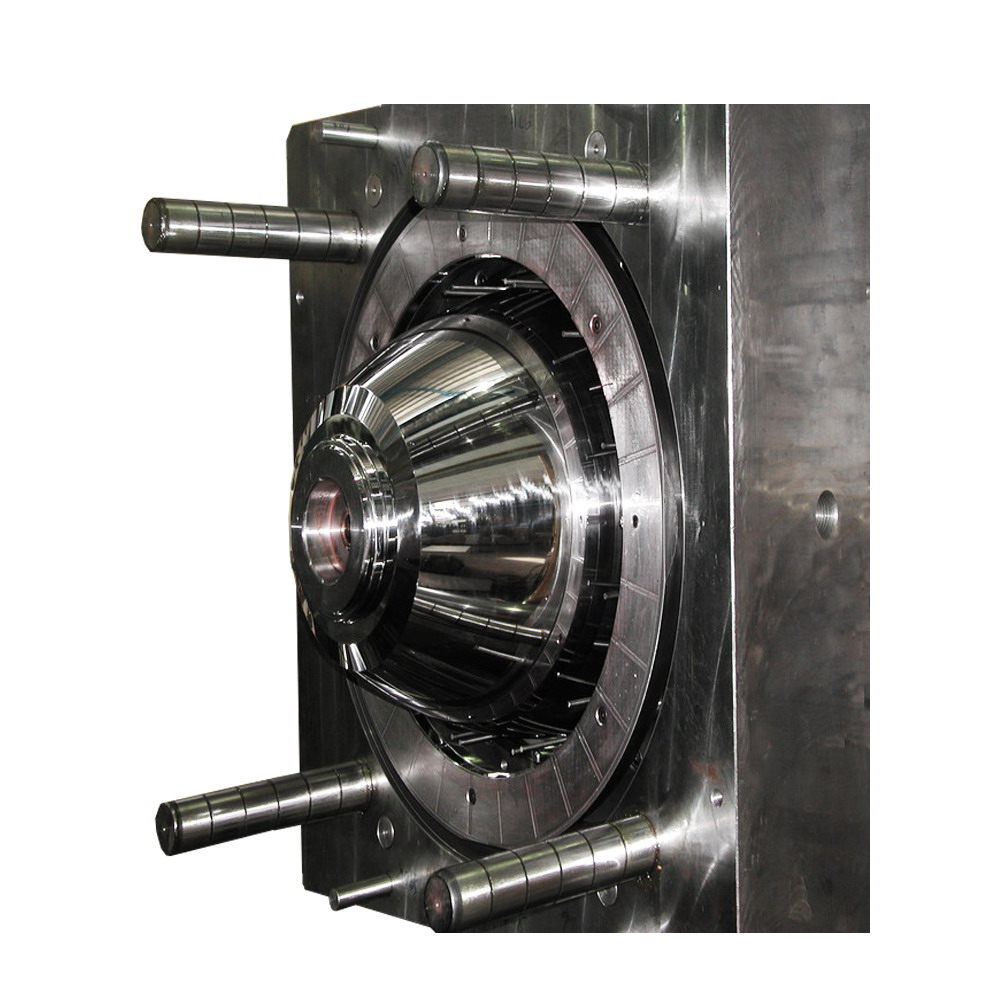

Core Mold Making and molding Technology

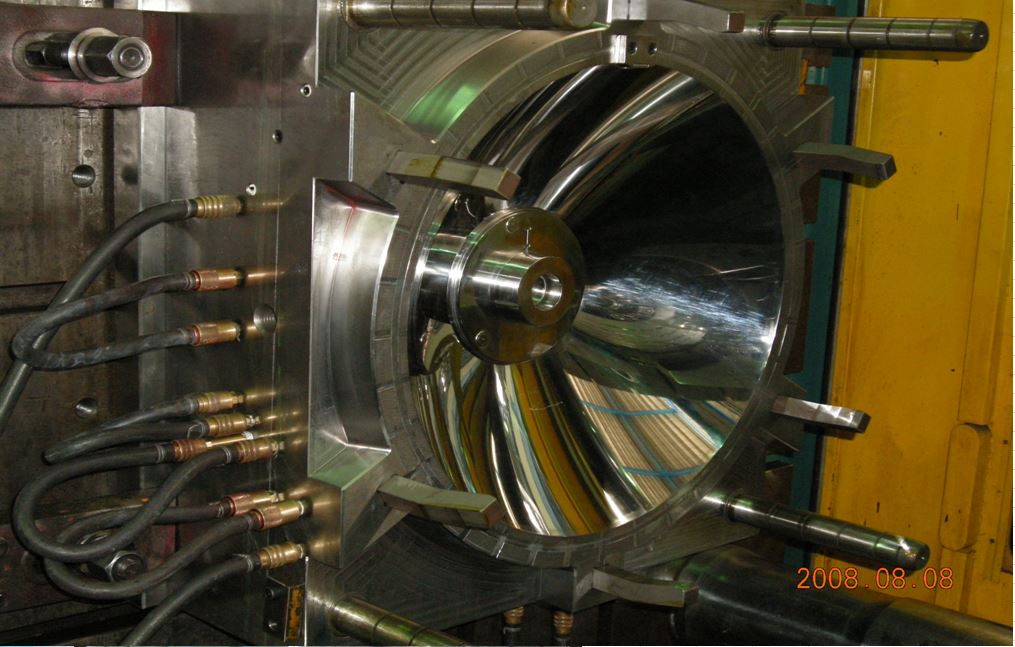

Core Mold Making and molding Technology - Application Examples:

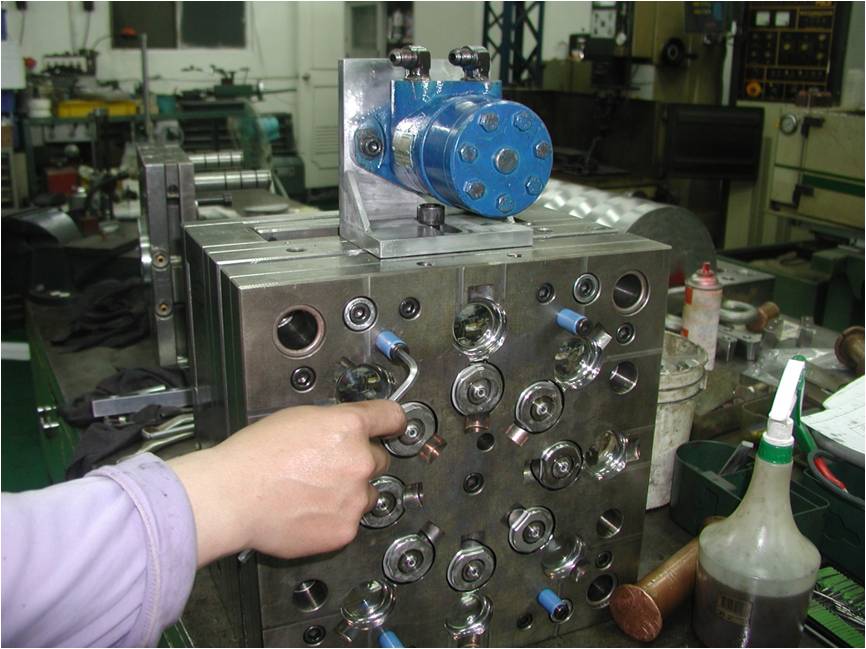

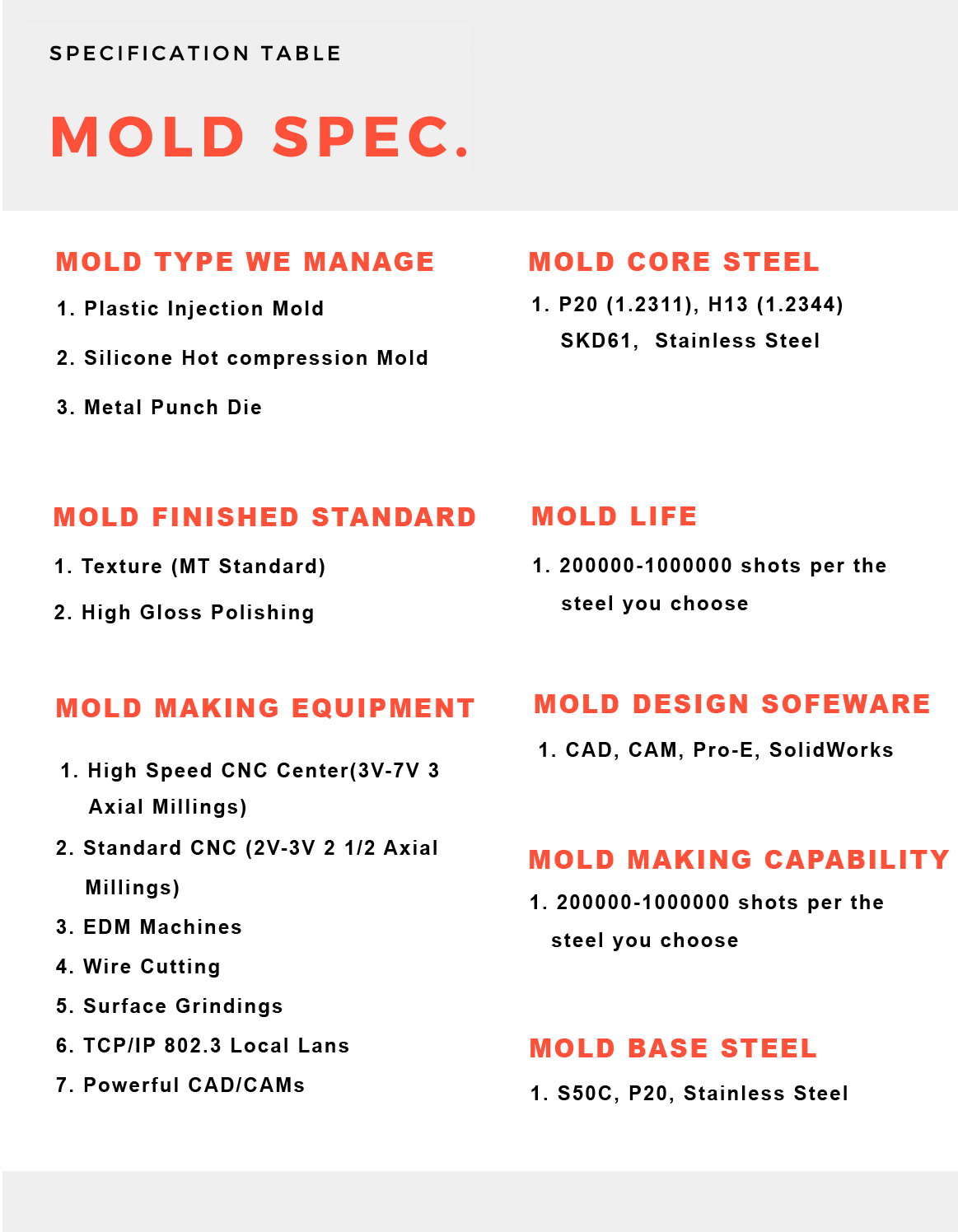

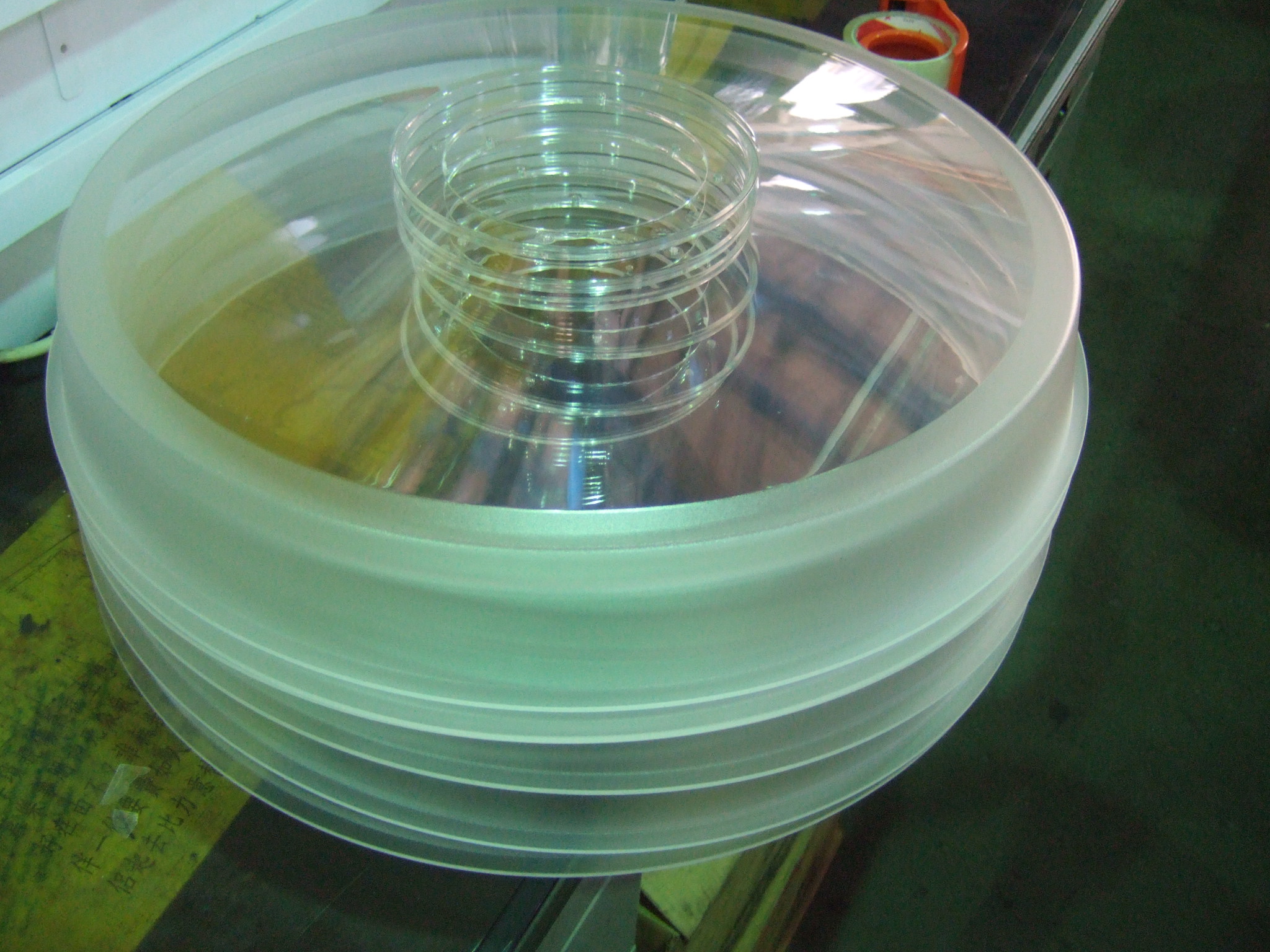

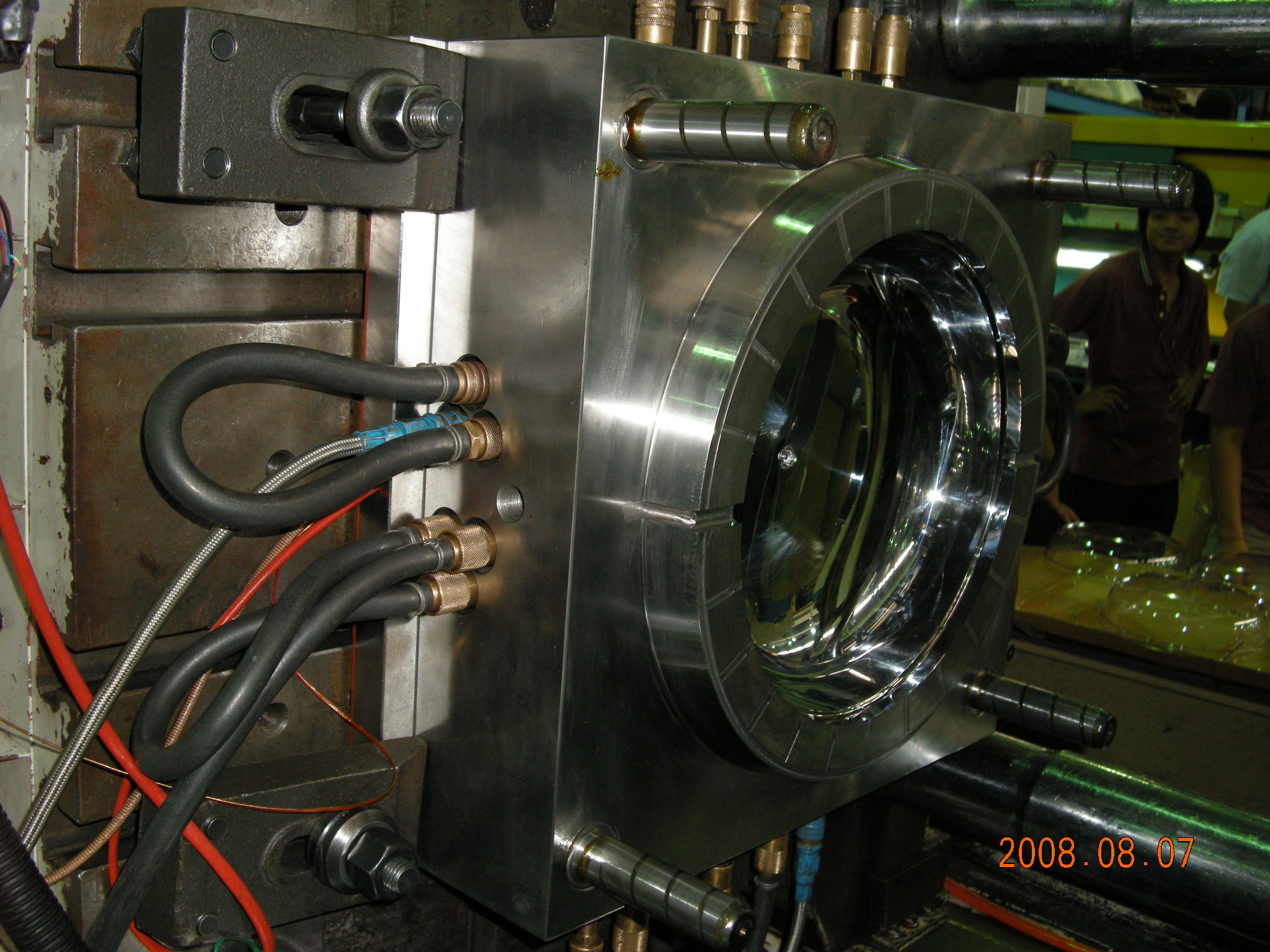

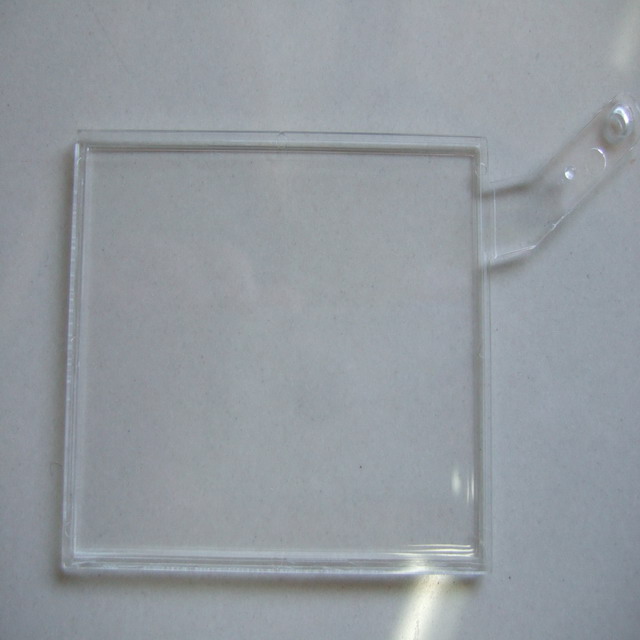

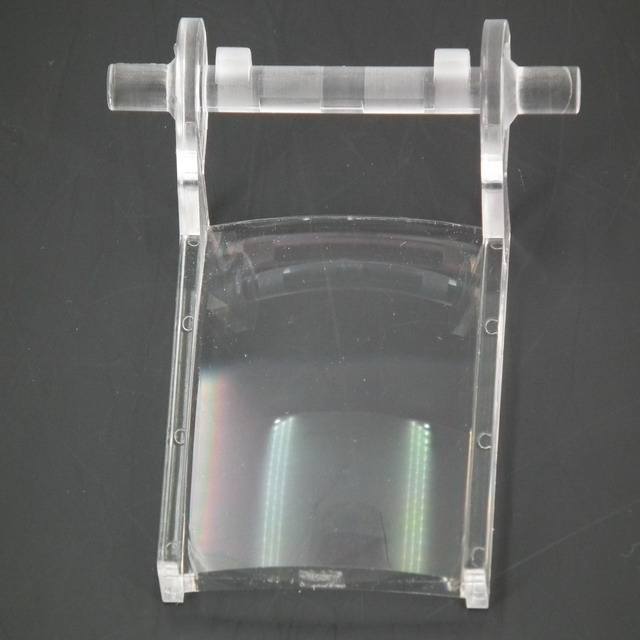

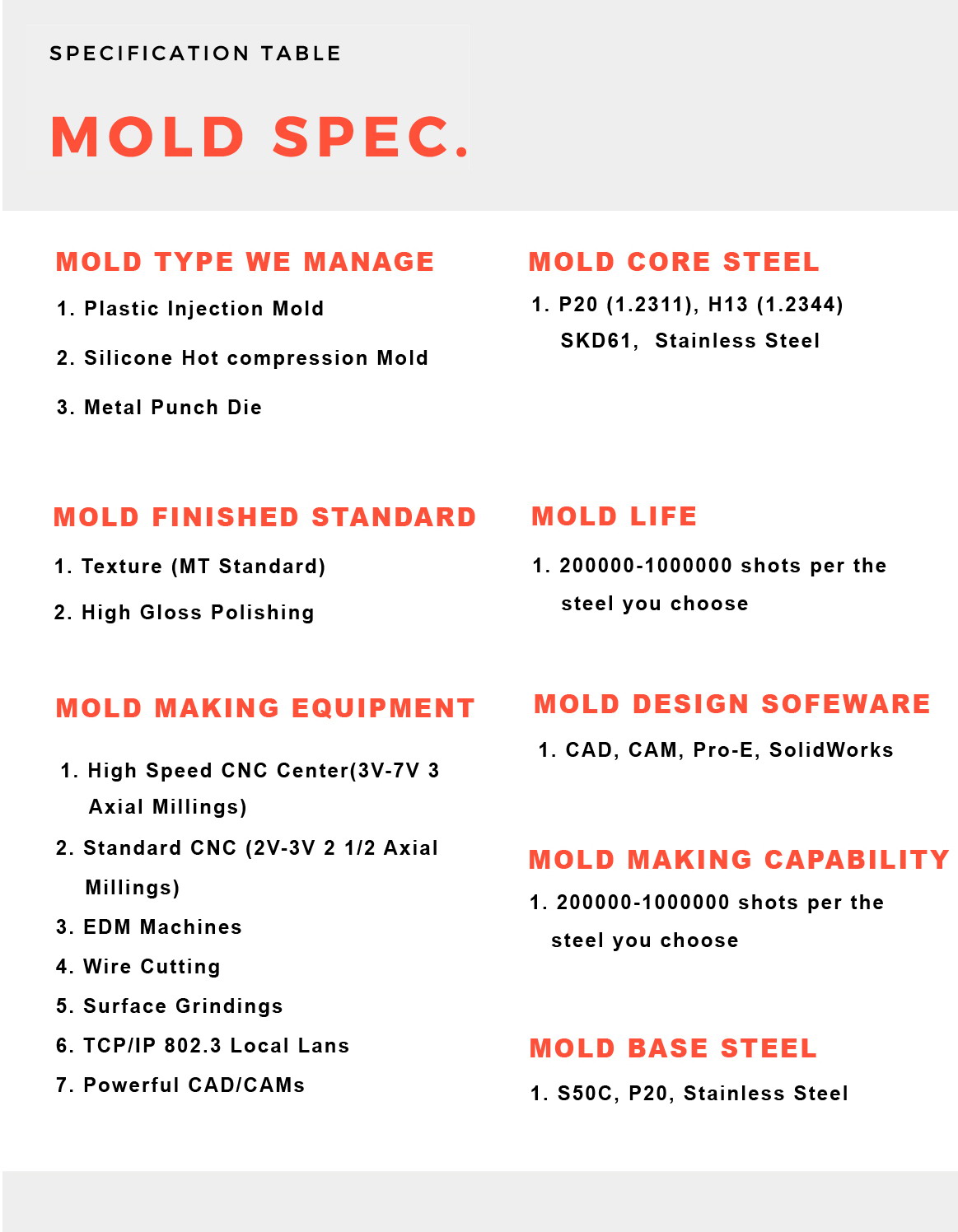

Intertech specializes in running various of precision plastic injection mold making and molding products projects , for examples, the project components of smart phone, electronic items, smart housing device, digital 3C devices, camera, optical lens, plastic medical parts..etc. We have full ranges of injection molding machine, 50-250T in house, 200-3000T in associated party.

We have small size of screw shot volume with high speed injection machine for running the kind of thin wall item mold and molding project for customer. We have gas assisted equipment for testing any gas assisted parts project mold and molding.

Intertech’s engineering experience and knowledge includes the application of the materials of plastics, silicone rubber, liquid silicone rubber and metal etc. I f customer have different material to be applied, processing and assembly, we can help customer to make the proper injection mold and molding, compression mold and molding, metal die and punching parts.

Secondary processing, for examples, printing, spraying, assembly, packing & shipping to customer’s appointed destination can be managed very well in Intertech per customer requirements. In our team association, we have the technology and equipment needed for secondary processing. Welcome to send your project to us !

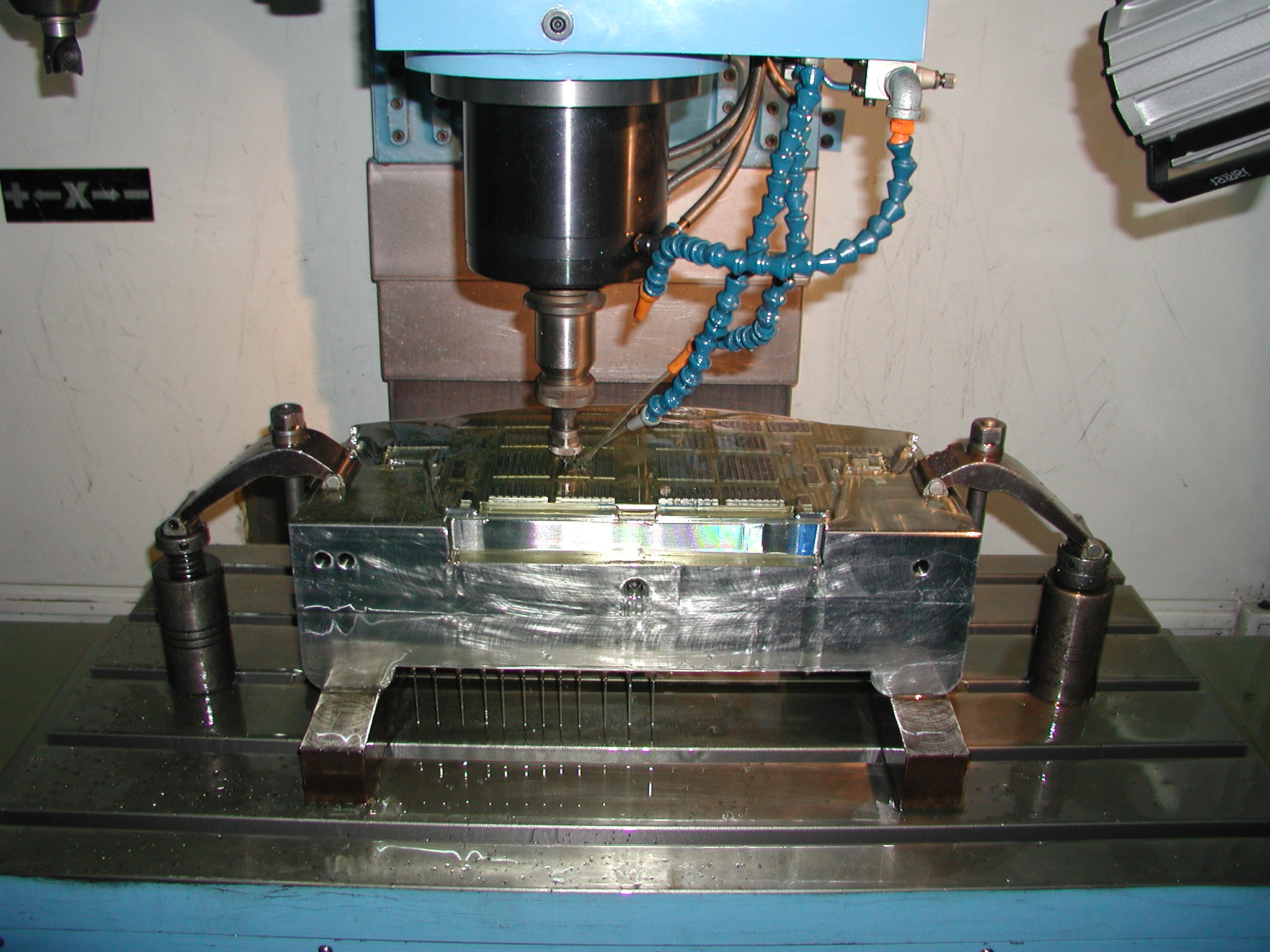

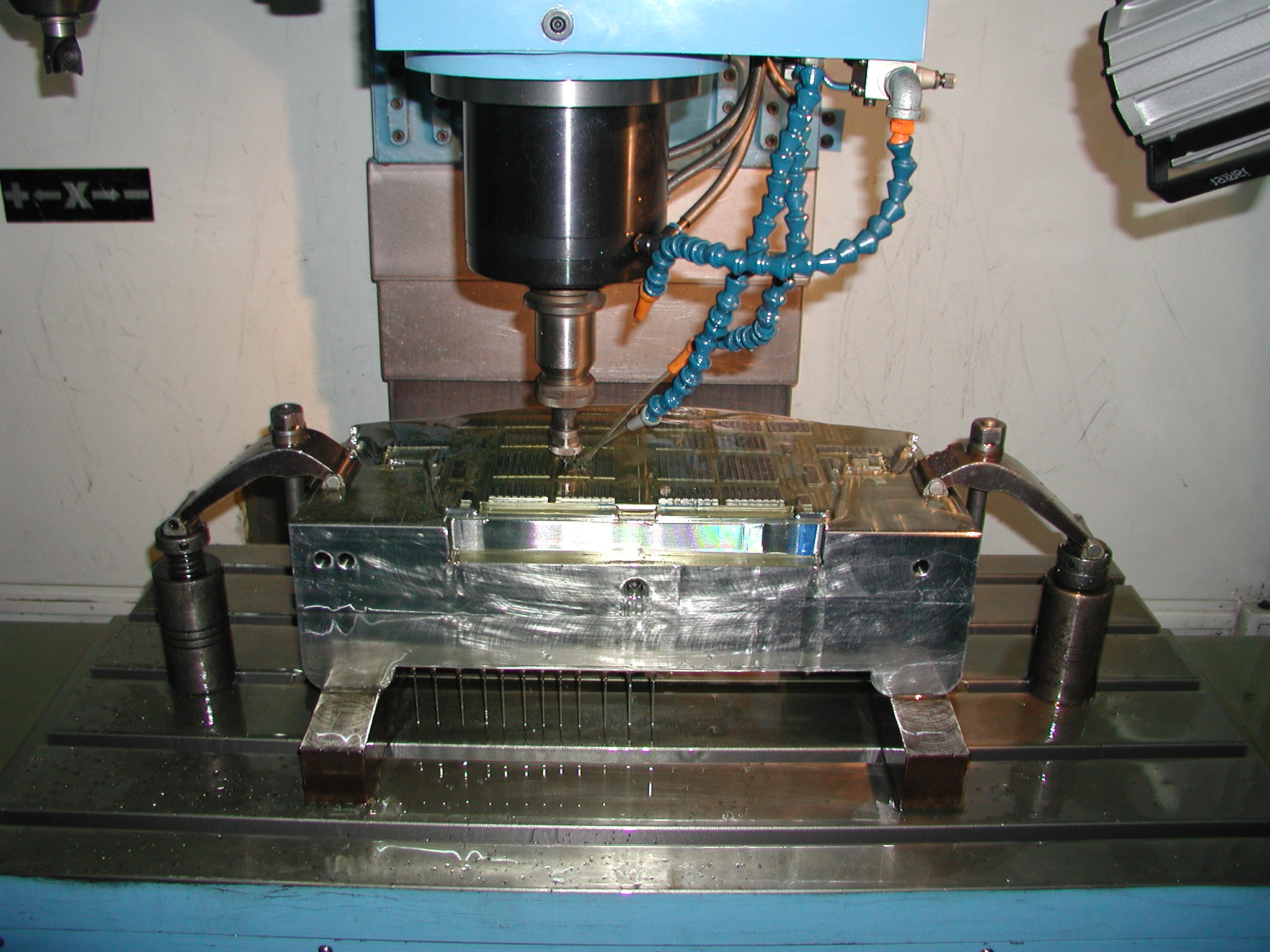

Taiwan Mold and Molding Factory:

l Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

l We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

l With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

l We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

Intertech - Quick Look :

l If you want to have your product to reverse manufacture,

we can help you with our rich manufacturing experience.

l If your current supplier is becoming cost prohibitive,

we can help you to find a cost effective solution.

l You can send samples, and we can design, manufacturer and ship a finished product to USA or wherever the place you want us to export.

l We can work out total cost of the project and the cost per piece.

l If you are saling some products now, we can help you to develop better products idea and manufacturing it with the best possible solution supply chain in Taiwan, including product packing and printing supply.

We will need you to send us all your project detail to us, so that

we can study and send you our report.

Please send all your 2d, 3d, and all correspondence to our direct

emails (for fast communication),

we will response as soon as possible...