Wish you Merry X’mas & Happy 2019 !🎉😃💖🎁

Intertech Machinery Inc.

https://www.taiwanmoldmaker.com/

https://intertech.en.taiwantrade.com/

http://www.intertech.net.tw/

http://plasticmoldmaker.blogspot.tw/

https://intertech.en.alibaba.com

2018年12月24日 星期一

2018年12月22日 星期六

Mold Design Support – Gating inlet design

Mold Design Support – Gating inlet design

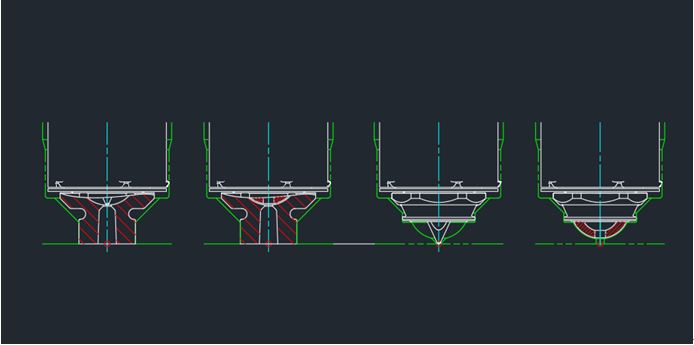

The gating inlet diameter and its type will also affect the number of gating and its allowed gating mark.

Please refer to above sketch, counting from left side, figure 1 and 2 – these are open type gating inlet.

Its advantage is that there can be a larger amount of feed volumn, and its gating number can be lesser.

But its disadvantage is that it will leave a material head and a large gating mark on the product surface.

Please refer to above sketch, counting from left side, figure 3 and 4 – these are pin type gating inlet.

Its advantage is that it will leave smaller gating mark, and its disadvantage is that it flow volumn is

smaller, so that it will require more gating inlet points.

All above points/types are needed to be considered by customer, and Intertech will provide our

Professional support for helping customer to make the best decision.

https://www.taiwanmoldmaker.com/articles/gating-inlet-design

https://www.taiwanmoldmaker.com/

https://intertech.en.taiwantrade.com/

http://www.intertech.net.tw/

http://plasticmoldmaker.blogspot.tw/

https://intertech.en.alibaba.com

https://www.facebook.com/Plastic-mold-1081123818582123/

https://www.linkedin.com/in/taiwan-mold-maker-injection-molding-factory-743a6570/

intertech@seed-net.tw

-Tel: +886 2 28334646 -Fax: +886 2 28334700

Contact: Deb Hsien

Skype: debbyhsien

WhatsAPP: +886932866329

2018年12月18日 星期二

Starting from 2017, the global environment protection issue makes the raw material supply is in short often and the price is up and up again, no stop, till now, it has been increased up to 20%.

Please read some news.

See more :https://www.rubbernews.com/article/20180430/NEWS/180439993/market-forces-tighten-silicone-sector-supply-spike-prices

Ps. Intertech is professional in making silicone mold and molded product. Welcome to send us your project

https://www.taiwanmoldmaker.com/

https://intertech.en.taiwantrade.com/

http://www.intertech.net.tw/

http://plasticmoldmaker.blogspot.tw/

https://intertech.en.alibaba.com

-Facebook

https://www.facebook.com/Plastic-mold-1081123818582123/

-Linkedin

https://www.linkedin.com/in/taiwan-mold-maker-injection-molding-factory-743a6570/

-Email

intertech@seed-net.tw

-Tel: +886 2 28334646 -Fax: +886 2 28334700

Contact: Deb Hsien

Skype: debbyhsien

WhatsAPP: +886932866329

AKRON—Tightness in silicone supply is straining the market, bringing on higher prices and causing trouble for steady sources, with no relief in sight until at least 2019, industry insiders said.

"Lead times have certainly increased, by several weeks in some cases, and there are a few grades which have become more difficult to come by, but we're proactively managing these with our vendors as well as our customers," Zack Beier, director of purchasing at Q Holding Co., which manufactures silicone products for the automotive, medical and aerospace industries, said in an email.

For Erick Sharp, president and CEO of Ace Products and Consulting L.L.C., customers who use silicone are contacting him both to get a feel for the market and to try to find alternatives to get past their own supply woes, he said.

"Some of them are in more critical places, and some of them are just trying to be pre-emptive, because they're seeing what's going on out there. They're seeing if it's legit and how long it's going to last," he said.

The shortage started to become more visible within the past year, as silicone facilities worldwide have fallen behind necessary demand, said Alex Sechi, senior account manager, Americas, for BRB International B.V., a formulator and producer of silicones.

"What we see is that it's really a supply/demand issue," Sechi said. "The demand has increased all over the world. If you look at the economic news, all countries are doing well and growing again. … The output of the plants for global capacity is not what it was in the past, plus the demand is growing, which is creating a gap."

For Greg Heden, marketing manager of First Continental International, which distributes chemicals and other raw materials directly from mostly Chinese manufacturers, silicones have been its largest expanding area for the past couple of years. The chemicals distributor works with several silicone manufacturers in China, but doesn't disclose its sources, though customers are able to approve and qualify materials.

Global demand for silicone is high in all regions, not just China or North America, said Eric Bishop, North America marketing manager for Shin-Etsu Silicones of America.

Silicone demand in 2017 saw one of its strongest years since the recession, according to Kent Furst, manager, polymers and materials, at Freedonia Group.

"The end consumer is starting to have trouble getting material now," Sharp said. "They're asking customers for more, and that volume's getting restricted down, and some people can't even get the level they were getting."

See more :https://www.rubbernews.com/article/20180430/NEWS/180439993/market-forces-tighten-silicone-sector-supply-spike-prices

Ps. Intertech is professional in making silicone mold and molded product. Welcome to send us your project

https://www.taiwanmoldmaker.com/

https://intertech.en.taiwantrade.com/

http://www.intertech.net.tw/

http://plasticmoldmaker.blogspot.tw/

https://intertech.en.alibaba.com

https://www.facebook.com/Plastic-mold-1081123818582123/

https://www.linkedin.com/in/taiwan-mold-maker-injection-molding-factory-743a6570/

intertech@seed-net.tw

-Tel: +886 2 28334646 -Fax: +886 2 28334700

Contact: Deb Hsien

Skype: debbyhsien

WhatsAPP: +886932866329

Intertech's mold cavity design support

Intertech's mold cavity design support

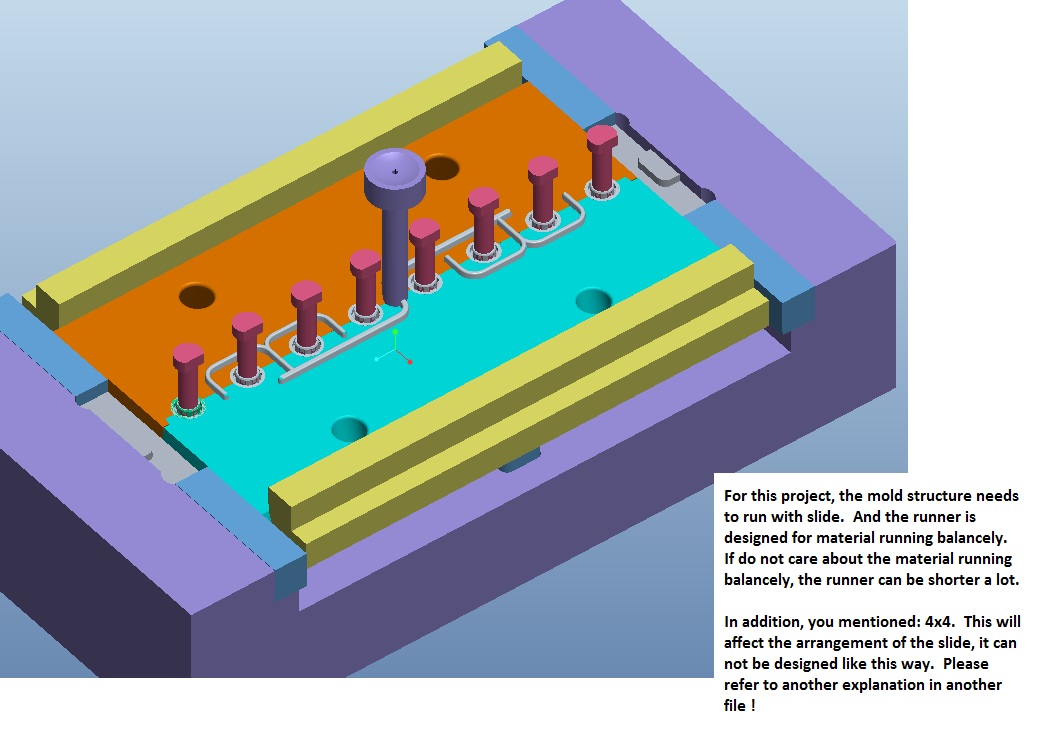

Custom askes us :

What is reason for choosing the layout as one long array 1 x 8, and not putting them up as a 4 x 4. (this would minimize the runner) ?

Our Support:

For the parts that needs to run with slide structure in mold, better the runner is designed for material running balanced.

We explain this with three mold cavity design sketches in following contents.

We give our suggestion: the best design is sketch A (please refer to the following sketch).

We explain this with three mold cavity design sketches in following contents.

We give our suggestion: the best design is sketch A (please refer to the following sketch).

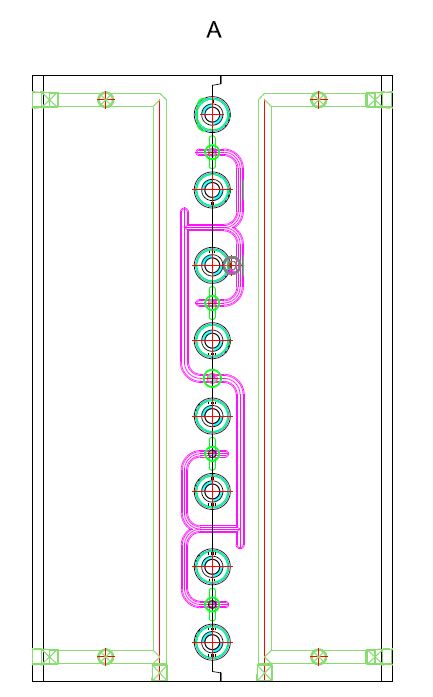

- Sketch A: is designed as per the material running balancely (the present design)

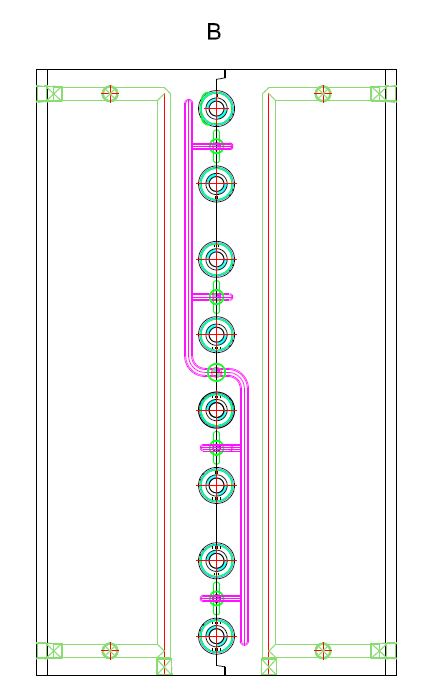

- Sketch B: runner can be shorter, but material running is not that balanced.

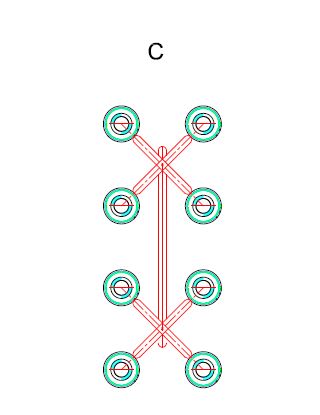

- Sketch C: this means your 4x4, this is not workable in this project.

Welcome to send your parts design, we will support you with our best cavity design proposal.

-Facebook

-Linkedin

-Email

intertech@seed-net.tw

-Tel: +886 2 28334646 -Fax: +886 2 28334700

Contact: Deb Hsien

Skype: debbyhsien

WhatsAPP: +886932866329

2018年12月5日 星期三

Baby nipple mold

Baby nipple mold

Intertech is a professional nipple, pacifier mold & baby nipple mold ,silicone baby nipple mold,rubber baby nipple mold services Supplier. Find more nipple mold, pacifier mold & baby nipple mold services information here or contact us for full service.

Baby nipple mold example

* 6 cavity high quality food grade liquid silicone rubber (LSR) baby nipple mold

* We make professional nipple mold which can produce with 100% food grade, soft, non-toxic, free of BPA silicone material, high temperature resistant and tear resistance, durable molding parts quality.

*Due to the liquid nature of the material, is easy to get flash. So, molds for LSR molding needs a super high precision mold making skill to complete this molding parts job with flashless or less goal.

Intertech is just such a professional and knowledgeable mould supplier in designing such LSR mold with the most optimized ejection and venting consideration to help our customer to build up their production line.

*The mold steel we use is 420 for food grade product to do the production which will not be rusty and very stable.

*For the LSR mold making and molding technology, we have much more experience in its application, and we can provide more solution than the other regular suppliers. Welcome to send us new LSR mold and molding project.

Rubber mold

-Capable to making silicone rubber molds in hot compression way or injection way.

-Mold cavity and mold size can be discussed upon your own requirements.

-Produced from SGS, FDA approved silicone rubber and LSR materials.

- We usually use silicone rubber in

the 40 to 70 shore A depending on customized requirements.

-Capable to manufacture tiny/small/little silicone molded parts for our customers.

-Supply with minimized flash free & mark free molded silicone products.

- Available in dealing with OEM manufacturing, ODM manufacturing, customized production,

contract manufacturing for silicone rubber mold & molding projects in Taiwan.

Silicone parts mold and molding application examples :

Our mold development for silicone has a wide range of product application lines as such : ear plug, label,

pad, gasket, protective frame, mobile phone protective cover, keypad, silicone rubber cord, check valve …etc.

More Applications:

-in Aerospace (silicone molded seals…)

-in Medical and health care (silicone molded membranes, seals…)

-in Electronic (connection insulators…)

-in Cooking / Baking (silicone molded spatulas…)

-in Agricultural (seals…)

Liquid Silicone Rubber (LSR) parts mold and molding application examples :

Available to produce extensive coloring or high transparency option in the finished molded LSR products.

Capable in managing medical grade, food grade, normal grade liquid . Silicone molded products projects.

Our mold development for liquid silicone has a wide range of product application lines as such : baby nipple,

pacifiers, seals, membrances, smooth surface LSR parts, respirator, medical mask, check valve, mouth guard,

tension ring, diving masks…etc.

For mold design, …

1. The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

2. Cutomer can send 2D, 3D, by .igs .stp, formats to us.

3. We can provide mold flow analysis service.

4. Mold design (with the best optimized mold water channel arrangement design and the best cycle time

performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture /

jig making or welding horn design and making are

available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making:

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold

steel grade for our customers. We have high quality German and Japan imports mold steel material to

proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed

, the mold cooling channel design will be checked, the operation style will be discussed, the molding

machine size will be determined and the mold mechanism in actual production movement will all be checked

as well. Only after our mold engineers discussing with our customers for the mold engineering in detail,

we will proceed with our mold making job.

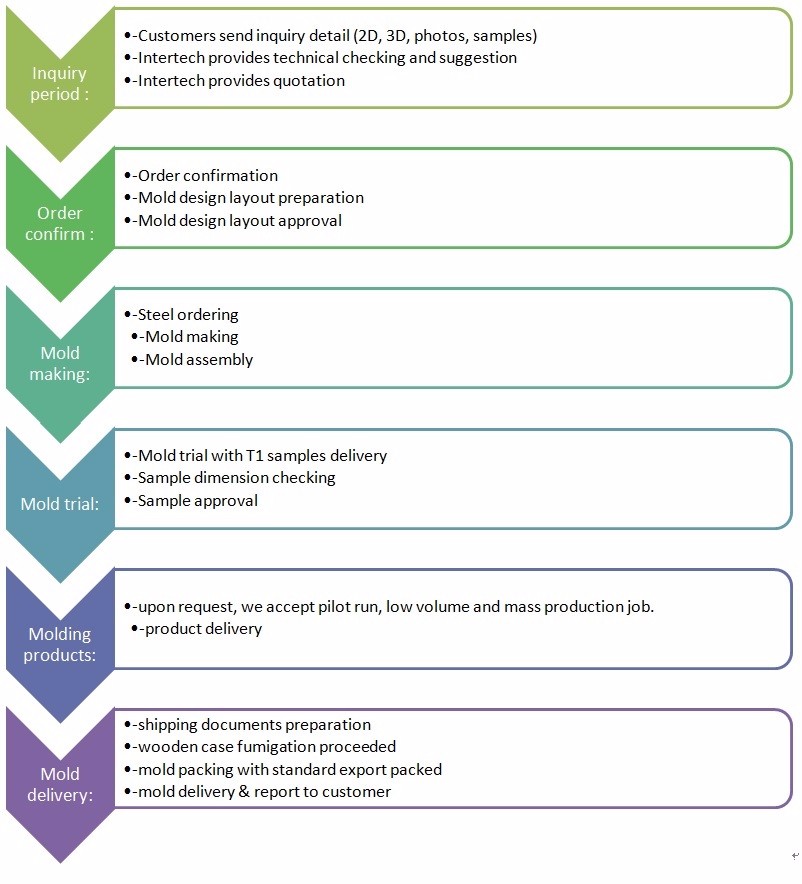

Mold Order Process

Mold Shipping Process

For Mold Inquiry, Customer Must prepare:

- Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?

訂閱:

文章 (Atom)