punch stamping die molded parts

Intertech is a leading maker for punch stamping die molded parts, metal punch die ,punch die set parts, punch and die set parts,punch press die, die springs parts and die press manufacturers in Taiwan. Intertech's services include prototyping, tooling, lab testing, sampling, pilot run, mass production and assembly.

Intertech makes precision punch stamping die molded parts, material with SUS 304 (for hiff latch), CnZu (for contact), bronze (for some contacts), alloy brass (for contact plate)..etc.

Intertech makes precision punch stamping die molded parts, material with SUS 304 (for hiff latch), CnZu (for contact), bronze (for some contacts), alloy brass (for contact plate)..etc.

Project example we provide :

M4 screw → contact plate (alloy brass) → washing → wire welding-soldering (wire 50mm, tinned

copper wire) → assembly final→ packing, including forming & hole drilling needs to be taken out.

Call holder

Call holder, stamped metal part based on alloy steel strip from 1.25mm thick (standard norm plate)

Sn galvanic plated !

-Make with punch die or progression stamping die – tool

-Make punch die or progression stamping die molded parts.

Sn galvanic plated !

-Make with punch die or progression stamping die – tool

-Make punch die or progression stamping die molded parts.

Contact plate

Contact plate, stamped parts based on alloy Brass C26800 H02 strip from 1.20mm thick, 1.27 micro

Ni plated !

-Make with punch die or progression stamping die – tool

-Make punch die or progression stamping die molded parts.

Welcome to discuss with us if you have any metal punch die molded parts project to be developed in Taiwan.

Punch die

We are a professional punch die making factory with Hasco standad, European standar quality.

We are experienced in building the dies for stamping, bening & punching for forming metal parts in OEM &

ODM projects.

ODM projects.

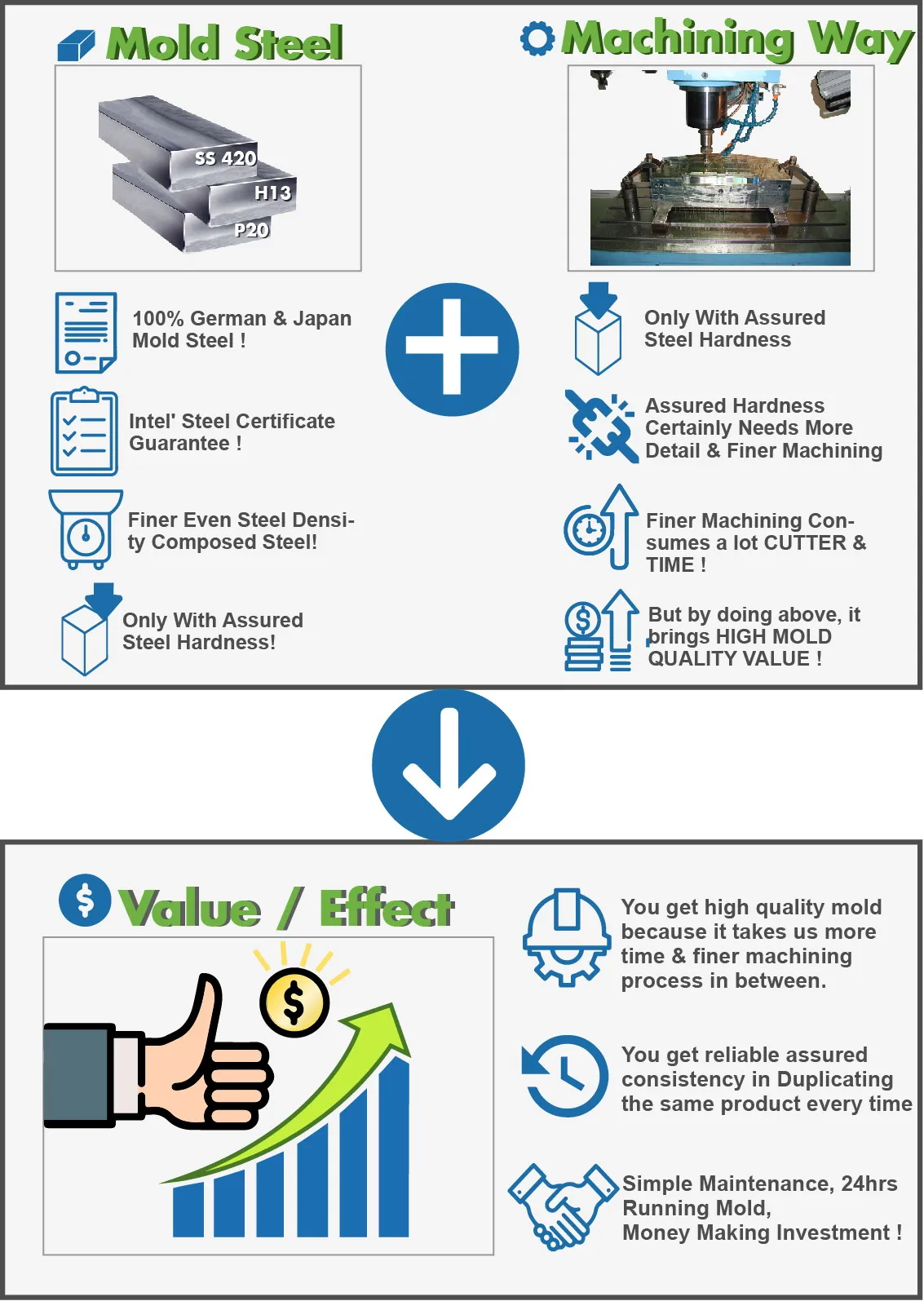

We use German and Japan imports steel to make our die sets, steel available with Buderus, Assab, AISI &

JIS, P20, H13, Starvax 420. - We are capable in dealing aluminum stamping die, sheet metal stamping die &

stainless steel stamping die.

JIS, P20, H13, Starvax 420. - We are capable in dealing aluminum stamping die, sheet metal stamping die &

stainless steel stamping die.

We provide cutomized molding, coating & assembly service as well.

We can also make a specialized tooling to cut or to shape material for custom-made projects need.

The press die we make can cover a wide range of products from simple metal parts to complex metal pieces.

Progressive pressing die and bending die is availabel per each project need.

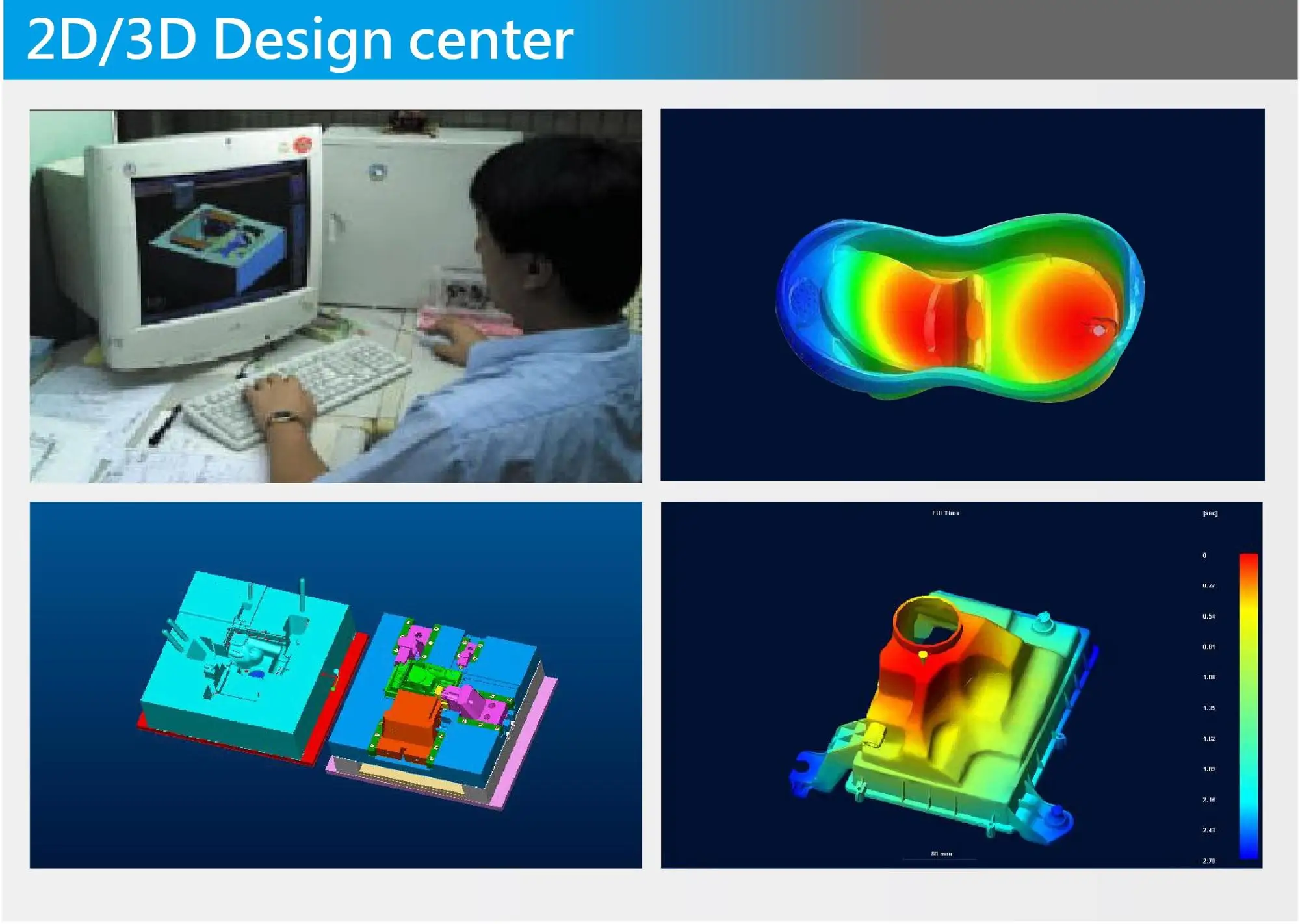

For mold design, …

1. The software we use includes Pro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

2. Cutomer can send 2D, 3D, by .igs .stp, formats to us.

3. We can provide mold flow analysis service.

4. Mold design (with the best optimized mold water channel arrangement design and the best cycle time

performance consideration design)

performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture /

jig making or welding horn design and making are available in Intertech with good experience !

jig making or welding horn design and making are available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making:

When making mold project, per customer’s requirement for mold steel material, we choose the suitable

mold steel grade for our customers. We have high quality German and Japan imports mold steel material

to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be

discussed, the mold cooling channel design will be checked, the operation style will be discussed, the

molding machine size will be determined and the mold mechanism in actual production movement will all

be checked as well. Only after our mold engineers discussing with our customers for the mold engineering

in detail, we will proceed with our mold making job.

mold steel grade for our customers. We have high quality German and Japan imports mold steel material

to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be

discussed, the mold cooling channel design will be checked, the operation style will be discussed, the

molding machine size will be determined and the mold mechanism in actual production movement will all

be checked as well. Only after our mold engineers discussing with our customers for the mold engineering

in detail, we will proceed with our mold making job.

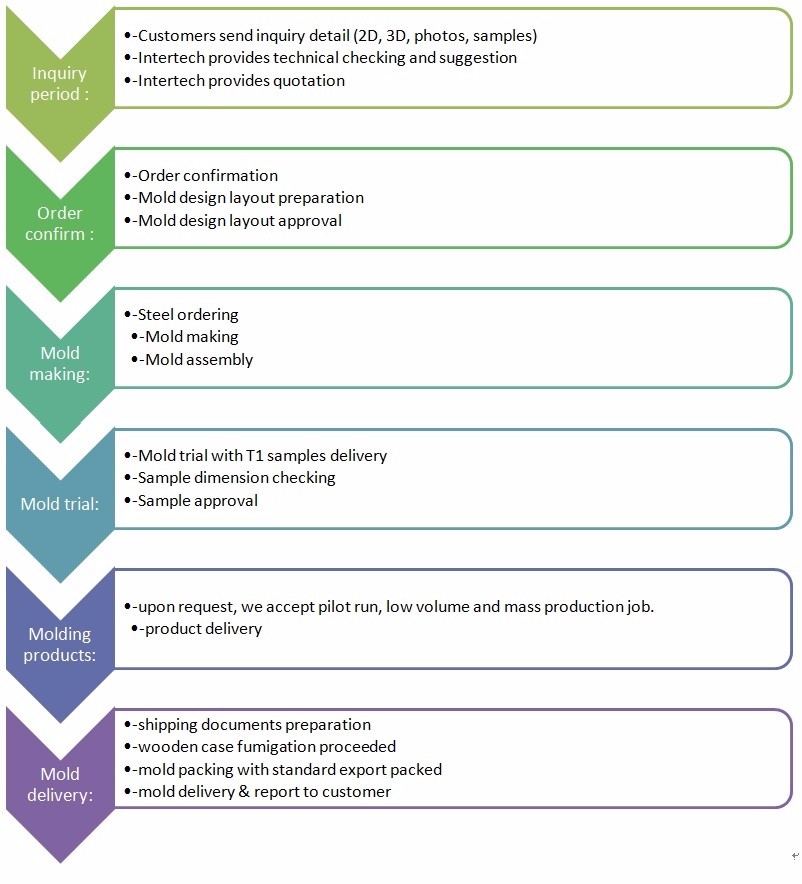

Mold Order Process

Mold Shipping Process

For Mold Inquiry, Customer Must prepare:

- .Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?

https://www.taiwanmoldmaker.com/

https://intertech.en.taiwantrade.com/

http://www.intertech.net.tw/

http://plasticmoldmaker.blogspot.tw/

https://intertech.en.alibaba.com

-Facebook

https://www.facebook.com/Plastic-mold-1081123818582123/

-Linkedin

https://www.linkedin.com/in/taiwan-mold-maker-injection-molding-factory-743a6570/

-Email

intertech@seed-net.tw

-Tel: +886 2 28334646 -Fax: +886 2 28334700

Contact: Deb Hsien

Skype: debbyhsien

WhatsAPP: +886932866329