Custom moulding solutions

Intertech is a leading maker for Custom moulding solutions, custom solutions, molding solutions and mold solutions manufacturers ,injection moulding custom solution,custom plastic injection moulding solutions in Taiwan. Intertech's services include prototyping, tooling, lab testing, sampling, pilot run, mass production and assembly.

Intertech Machinery, Inc. an expert of plastic injection industry, is a custom plastic injection molding factory in Taiwan dedicated to providing quality services.

Intertech Machinery Inc. offers you one stop plastic molding service,with FDA certificate from the plastic components design to mold making, plastic components molding and if necessary with plastic surface treatment such like chrome plating UV and PU painting until packaging.

Come to Intertech Machinery Inc. for one stop custom plastic moulding solutions. We are sure that you will be satisfied with the quality, service, price and promptly delivery.

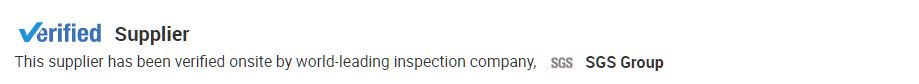

Project development

Intertech Machinery is good at manufacturing plastic mold components used in industrial and

packaging applications.

Per customer’s demand, we will discuss the raw material required, the color master batch

requires, mold making size required, molding machine size required, cycle time estimation,

production time calculation report…etc with customers. After that, parts design service, mold

engineering service, mass production arrangement, post assembly service or post machining

service are also provided.

Each mold and molding projects case, we will see client specifications to serve the needs of a

wide variety of industries. Our injection mold technology have D&B D-U-N-S compliant

working system and meets high industry standards. We can mold anyplastic, metal and rubber

projects for customers. We have advanced machinery equipment to provide small to larger

mold projects and also manufacture thermoplastic, engineering plastics, silicone rubber and

metal parts.

Highlight Points:

- Our professional service includes engineering, mold making, prototyping and tooling

- From single prototype to OEM and ODM high professional volume production, We can

- manage all our clients plastic injection molding requirements.

- Except making mold, we also provide injection molding service, compression molding

- service (especial for silicone rubber material compounding with various colors matching

- and production job for specific product need) or punch die production service.

- our injection mold testing machine available 50~250T in house, 300~3000T in associated

- party.

- per each project need, we also design and provide fixture and jig making service for

- stabilizing some easy deformed parts need.

- per customer’s need, we also provide chrome plated, painting, ultra-sonic welding,

- assembly or packing/printing service.

We provide low volume, pilot run of production job and mass production for customer.

Product Name | mold |

Plastic Material | PP , PE , ABS , POM , PET, PBT, Nylon + GF…..etc.

PC, PMMA Acraylic for transpartent product. |

Steel of Cavity & Core | Up to customer’s budget and productivity required,

we suggest the following steel grade:

Pre- harden steel : P20 (1.2311), P20+Ni…etc

Harfen Steel : H13 (1.2344) / NAK80…etc.

Stainless steel : ASSAB Stavax…etc |

Steel of Mold Base | Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20 |

No. of Cavity | Customized |

Hardness of Cavity & Core | Pre-Hardenss Steel : HRC 30~32+-1*

Heat Treatment Steel : HRC 50~52+-1* |

Core pulling or Ejection system | Depends on the Products.

Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc |

Mould Accessories | Compatible to DME/ HASCO Standard. |

Cooling System | In Core : Baffle or By pass cooling

In Cavity Plate: Chain drilling type colling |

Surface Finish | Up to the prodct’s requirement, Normal used : Texture, EDM maching , Polishing |

Mold Life | Up to mold steel grade, under ideal operation condition,

1. Pre-harden steel, min. 20~300000 shots

2. Harden / heat treatment steel : 60~800000 shots.

3. Stainless steel : 1 million shots. |

Runner | 1. Cold runner

2. Hot runner

3.cold runner +hot runner |

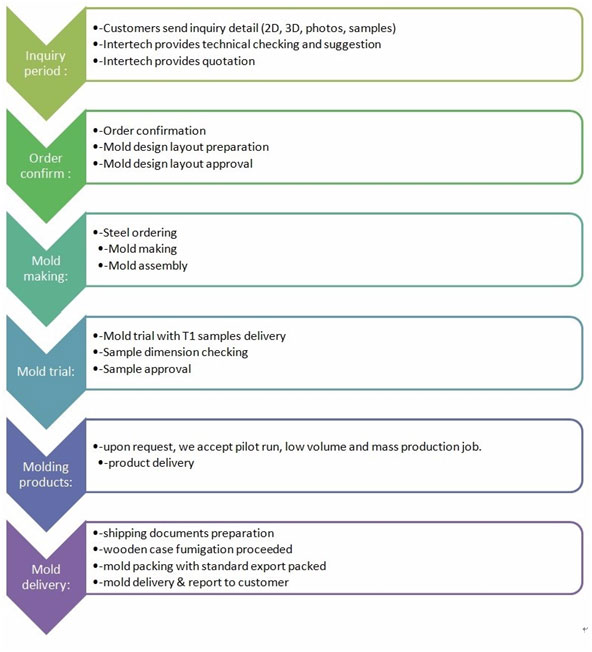

Delivery time | 40~50 days , presenting T1 samples |

Packing | Standard Wooden Case |

Production | We can also provide Pilot Run production and molding production |

For Mold Inquiry, Customer Must prepare:

- Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?